![]()

Single dough filled pasta

![]()

Double dough filled pasta

![]()

Option

Short pasta

![]()

Option

Bologna pasta

![]()

Double

pasteurization

![]()

Stabilization

(+20°)

![]()

Freezing process

(-20°)

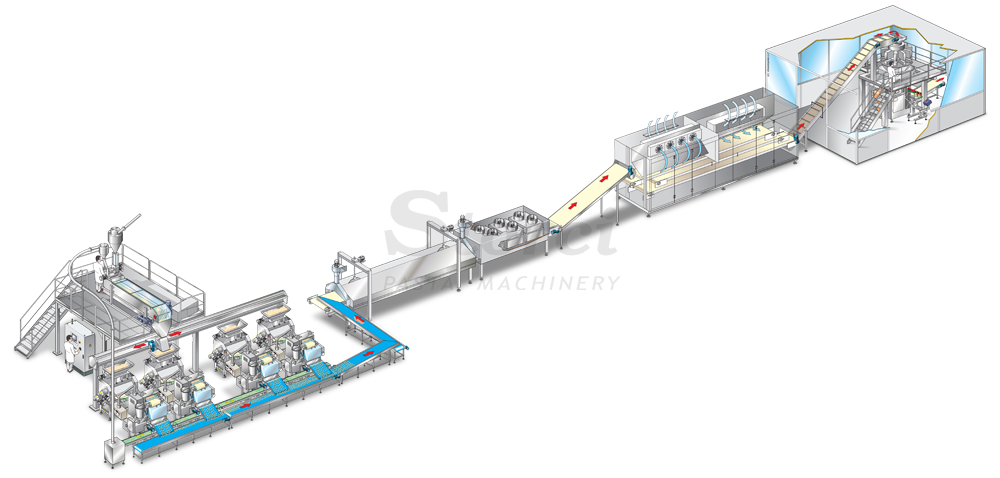

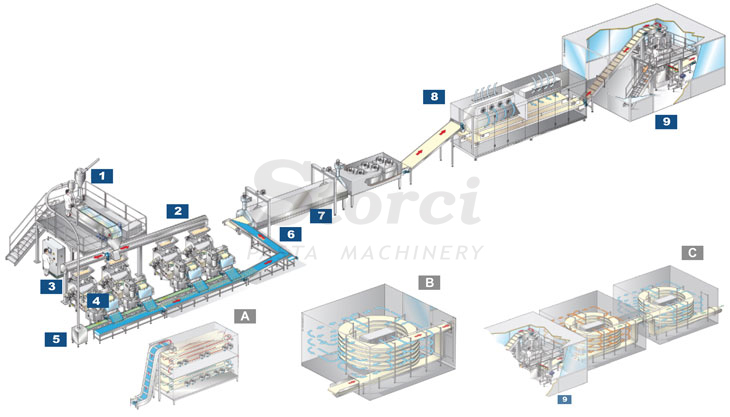

F/RP fresh filled pasta lines have been designed to reach the maximum quality and a long life-spam by a unique pasteurization process. High temperature drying systems together with freezing and double pasteurization systems are available for frozen or stabilized pasta. The best compromise between life-spam and product organoleptic characteristics. Thanks to the mixing technologies Premix®, beltmix and Bakmix, together with total vacuum technology, you can obtain high quality cooking mixtures and a bright yellow colour. The dough sheeters series - STF TV and VSF TV/MIX – allow you to apply total vacuum system to laminated pasta production: a great news in fresh pasta sector. Would you like to produce rough dough pasta, have total automatic pasta plants, increase your business reaching also the most demanding Customers? We will help you put your plans into action.

Play the video

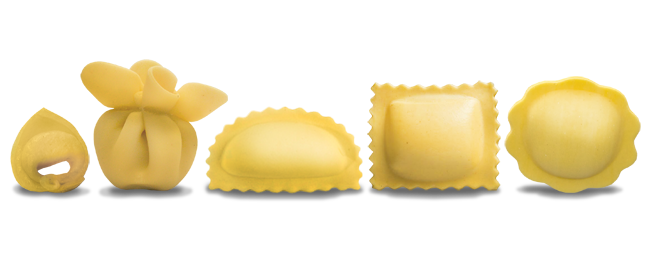

A complete catalogue of fresh filled pasta for a production attentively made like the traditional one

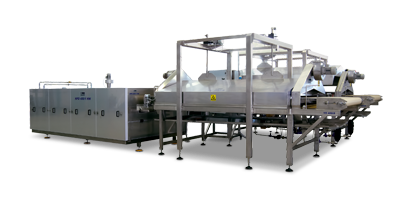

Proprietary technology pasteurizers developed in our R&D laboratory. The use of the vapour injection in the treatment area lets you have a quick heating up and a reduced superficial humidification of the products. Energy consumption considerably decreases in comparison to pasteurizers with internal boilers. For a good and particularly safe pasta.

F/SP pasta plants have been created to streamline the shelf-life of filled pasta, subject to a unique pasteurization process and stored at a temperature not higher than +4°C. Thanks to this technological process, you can obtain a good compromise between life-spam and product organoleptic characteristics. To get a good result, it is essential the use of excellent quality raw materials as well as establishing the correct pasteurization treatment and using high temperature air together with anti-contamination filtration system, during the following drying and cooling phases. Using separate rooms during the different phases and a white room for the packaging is strongly recommended.

F/DP lines have been created to streamline the shelf-life of filled pasta subject to a double pasteurization process and stored at a temperature not higher than +4°C. This technological process allows you to get a longer shelf-life than that one obtained by a single treatment. However, using separate rooms during the process phases is strongly recommended. The packages are then transported inside a first continuous spiral for a second pasteurization and subsequently into a second spiral for the final cooling. By this process you can obtain the longest possible shelf-life of a fresh product.

F/SDP lines have been designed for the production of stabilized filled pasta. This process can be done when reaching humidity specific levels and AW water activity. After the thermal treatment carried out by high performance special pasteurizers , the process requires an longer drying time until the reduction of humidity level requested for stabilized pasta standards is reached. The packages are then transported inside a first continuous spiral for a second pasteurization and subsequently into a second spiral for the final cooling. All the above mentioned phases result in a long shelf-life, also at ambient temperature (18°C approximately).

F/F pasta plants have been designed for frozen filled pasta. A long shelf-life, together with product excellent organoleptic characteristics, can be obtained by this technological process. It is essential, for a good result , to use raw materials of excellent quality, to control the pasteurization treatment and then go on with the freezing process in the shortest time possible, in order to avoid the contamination. A quick freezing process improves the final quality. The frozen product is then taken to the packaging dept. Using separate rooms for the different phases of the production is strongly recommended.

![]()

We have stored all the information that you can find in this page, together with other useful tips, in a easily readable document. Download our catalogue clicking here below. You will need Adobe Reader.